Industrial Engineering and Management

The centre is an international reference in business analytics through decision support systems for service and operations management, contributing also in service design, performance assessment and asset management.

Our core areas of application include Mobility/Transports, Retail/Industry and Healthcare, also with significant contributions in the Energy Sector and a strengthened collaboration with the Centre for Power and Energy Systems.

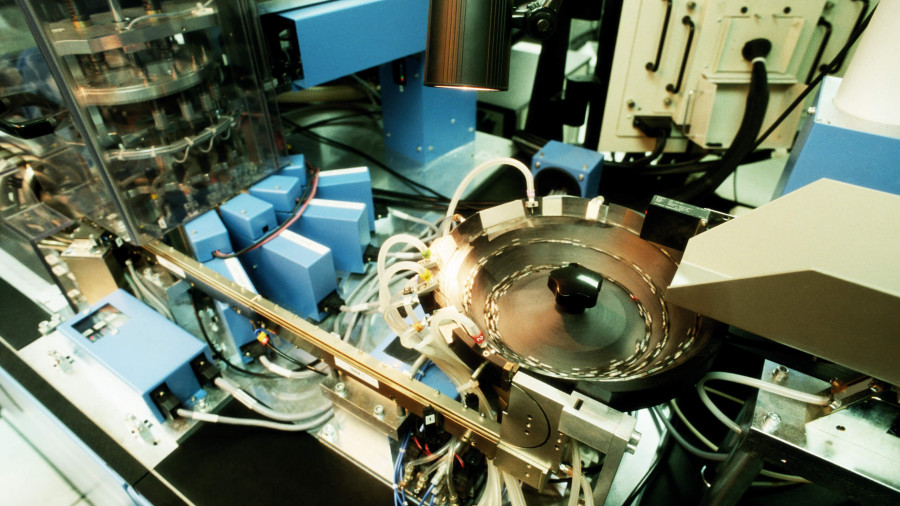

In the latest years, CEGI substantially contribute to Industry 4.0 initiatives (improving scheduling rules based on the additional information available in manufacturing systems).