About

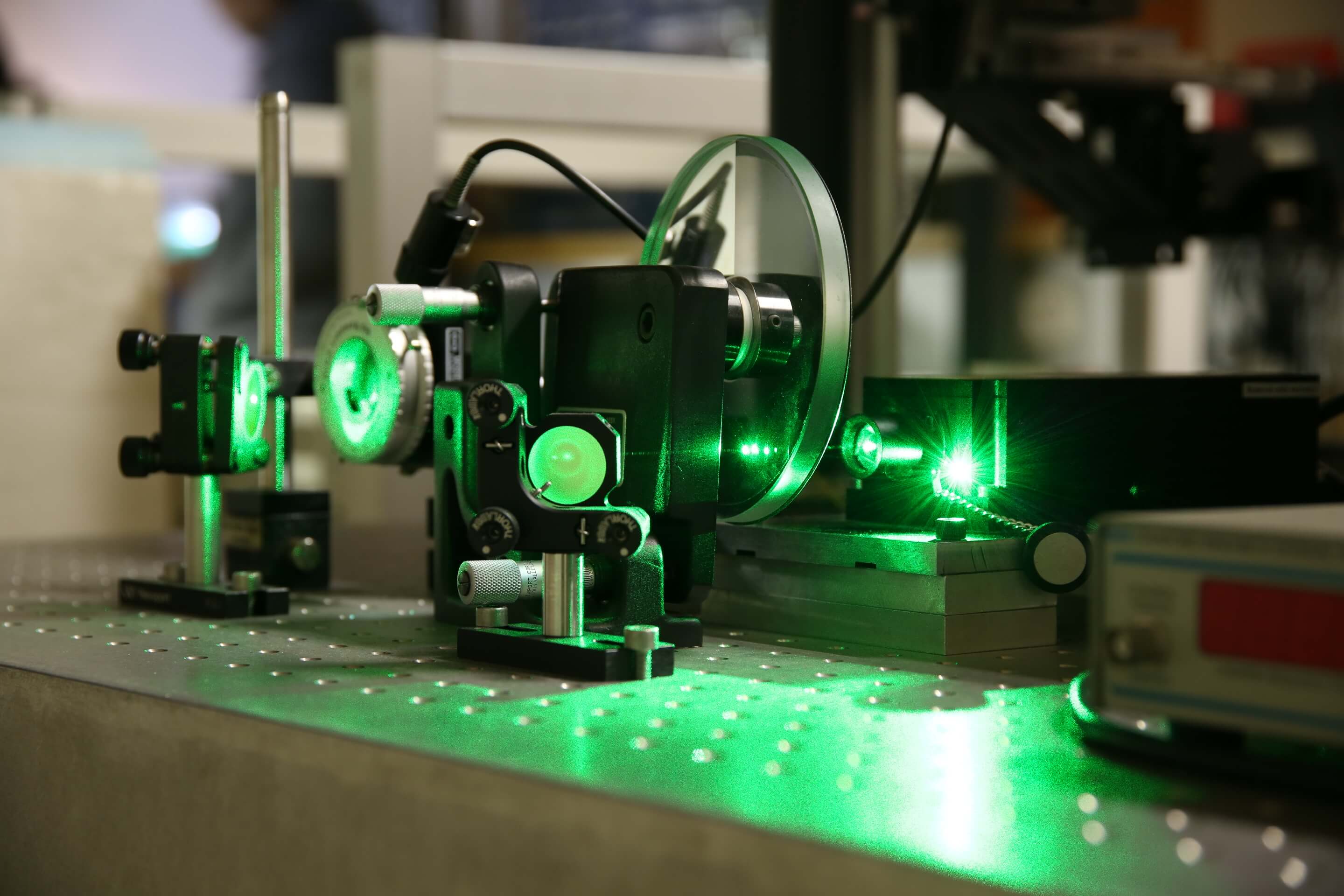

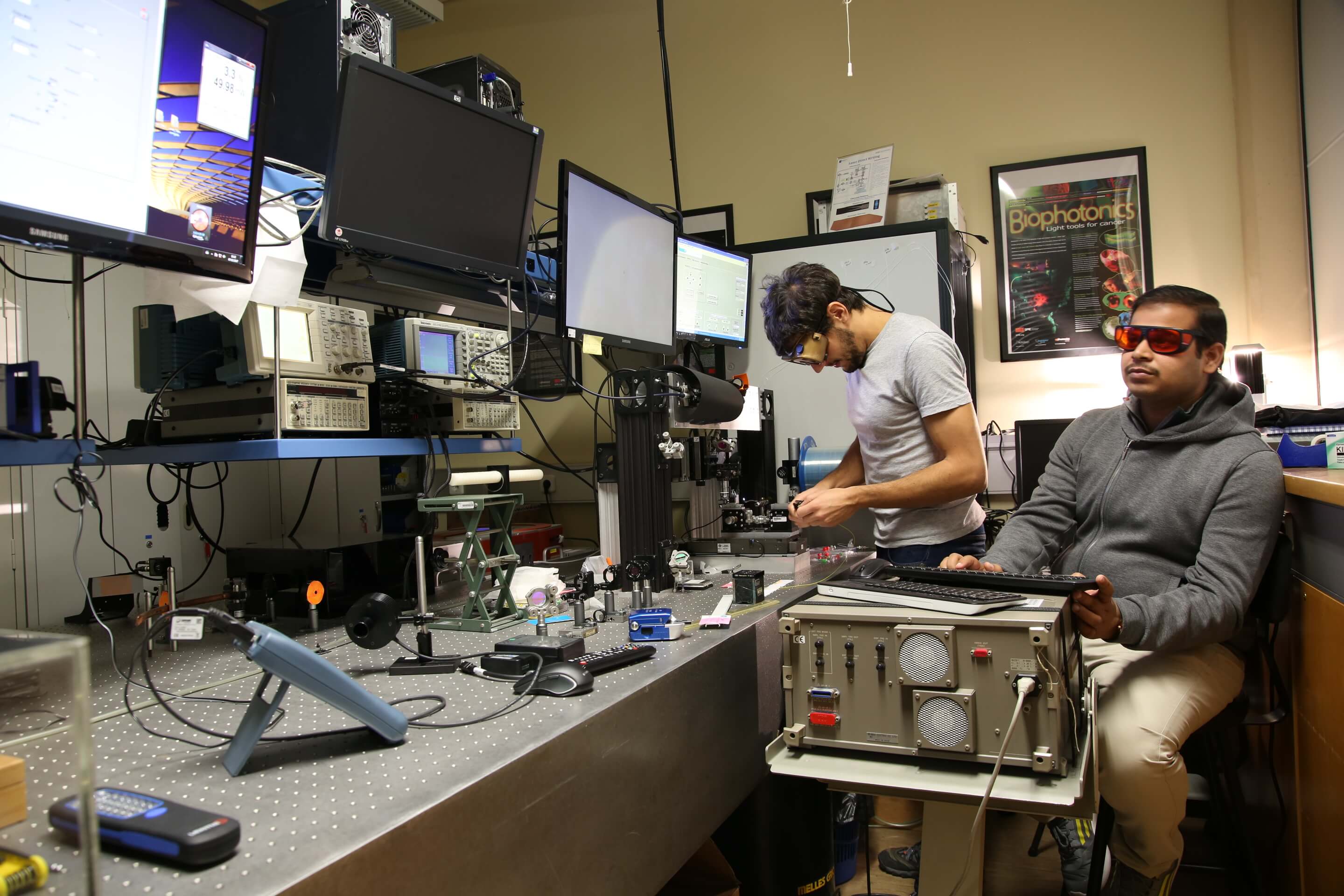

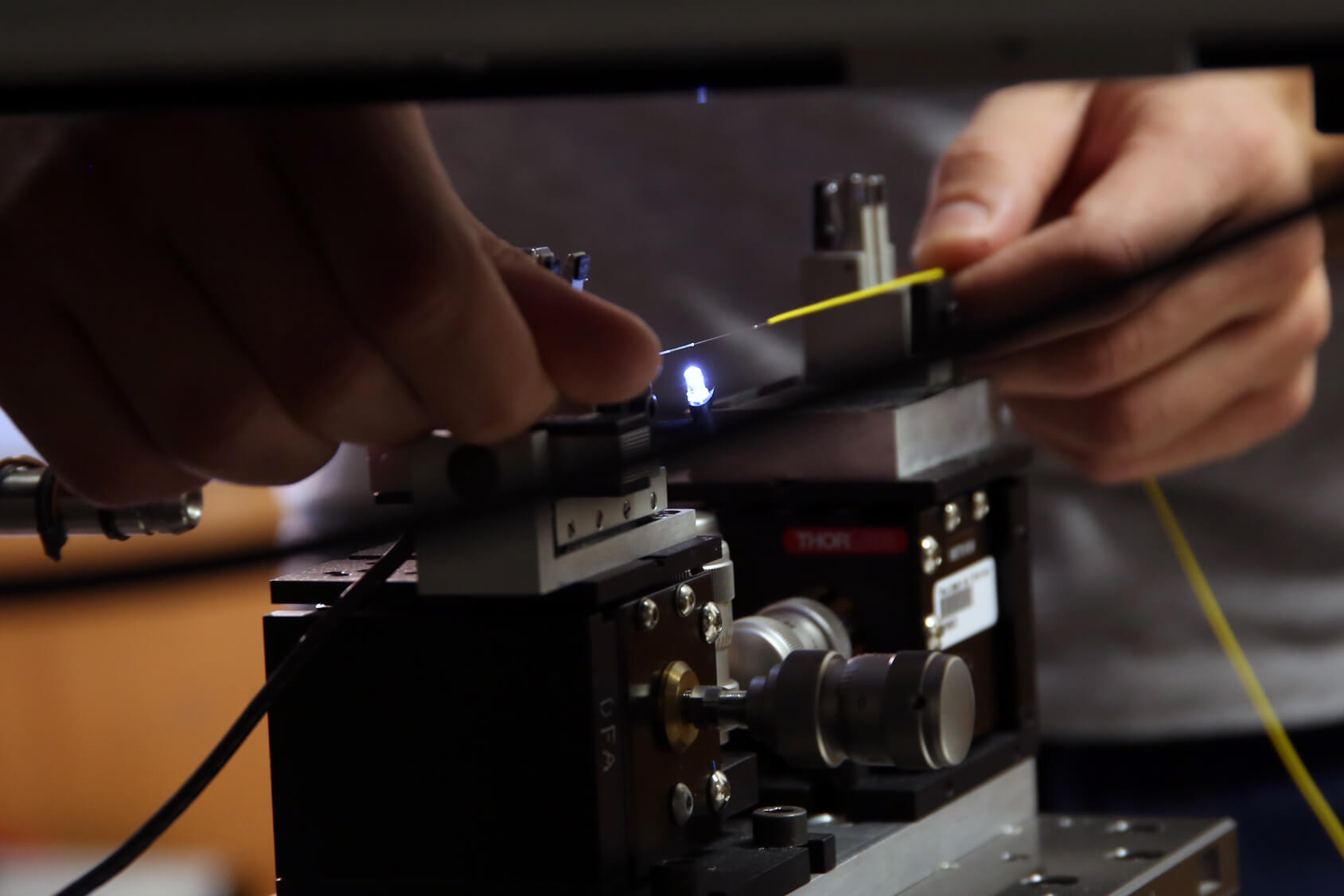

The Microfabrication laboratory explores traditional top-down microfabrication techniques and non-traditional based on laser direct writing processes to support the activities of other areas.

For example, microfluidics chips are produced to implement biosensors and micro and nanostructures. Bragg gratings are made by laser direct writing to implement new sensing heads that will lead to the development of better and more reliable sensing heads.