The beginning

In Portugal in the 1980s, the research on optical fibres was taking its first steps, and one of the most cohesive research groups was working in the city of Porto. The work in optical fibre communications, was at the origin of INESC TEC, at the time called INESC Norte.

The first paper published addressed electrical interferometric, reflective and micro-curvature sensors:

José Luís Santos, “Provas de Aptidão Pedagógica e Capacidade Científica”, 1989

The first PhD thesis concluded in this area is also authored by José Luís Santos ‑ “Multiplexagem e Processamento de Sinais de Sensores de Fibra Ótica” (1993).

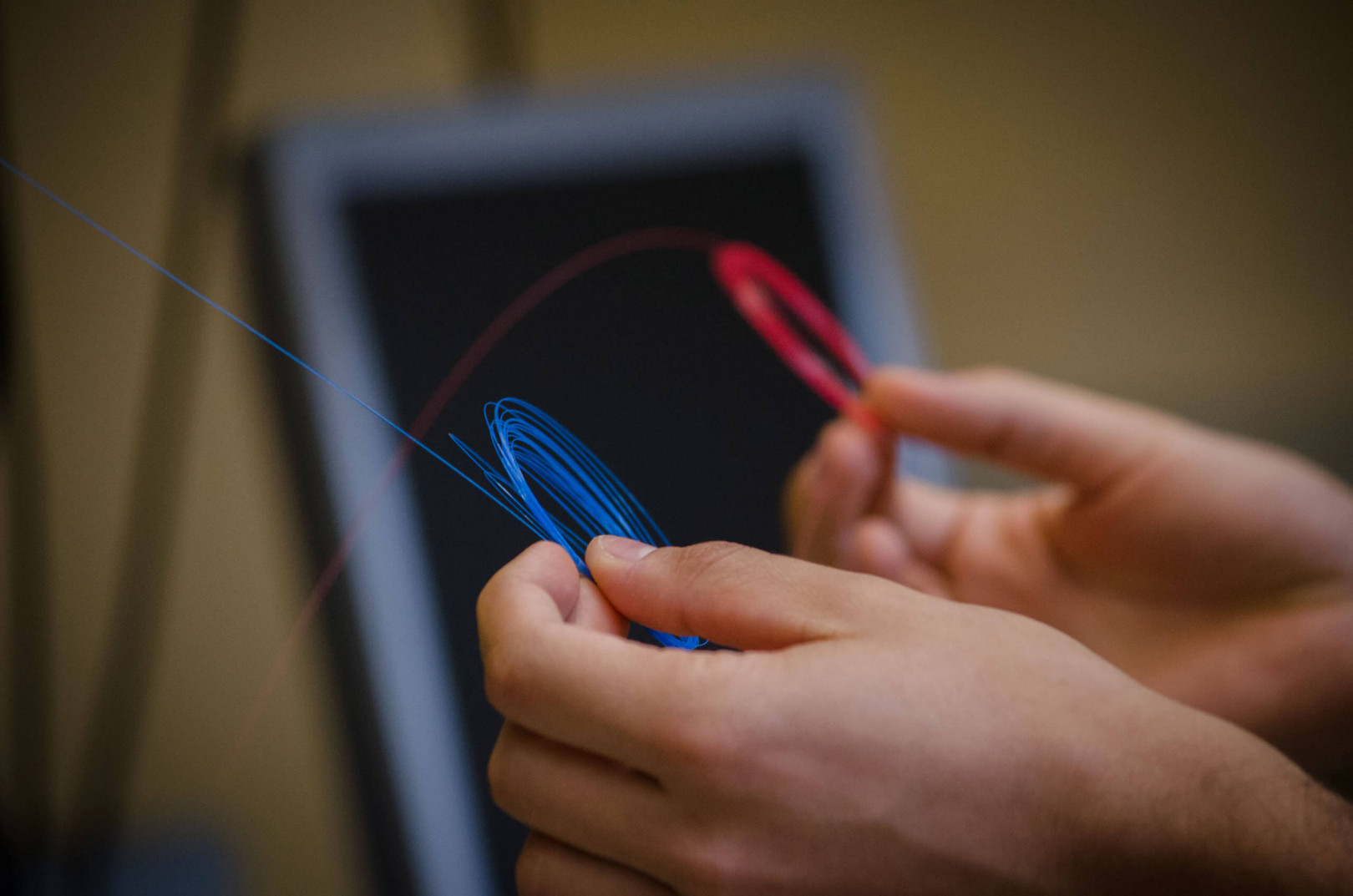

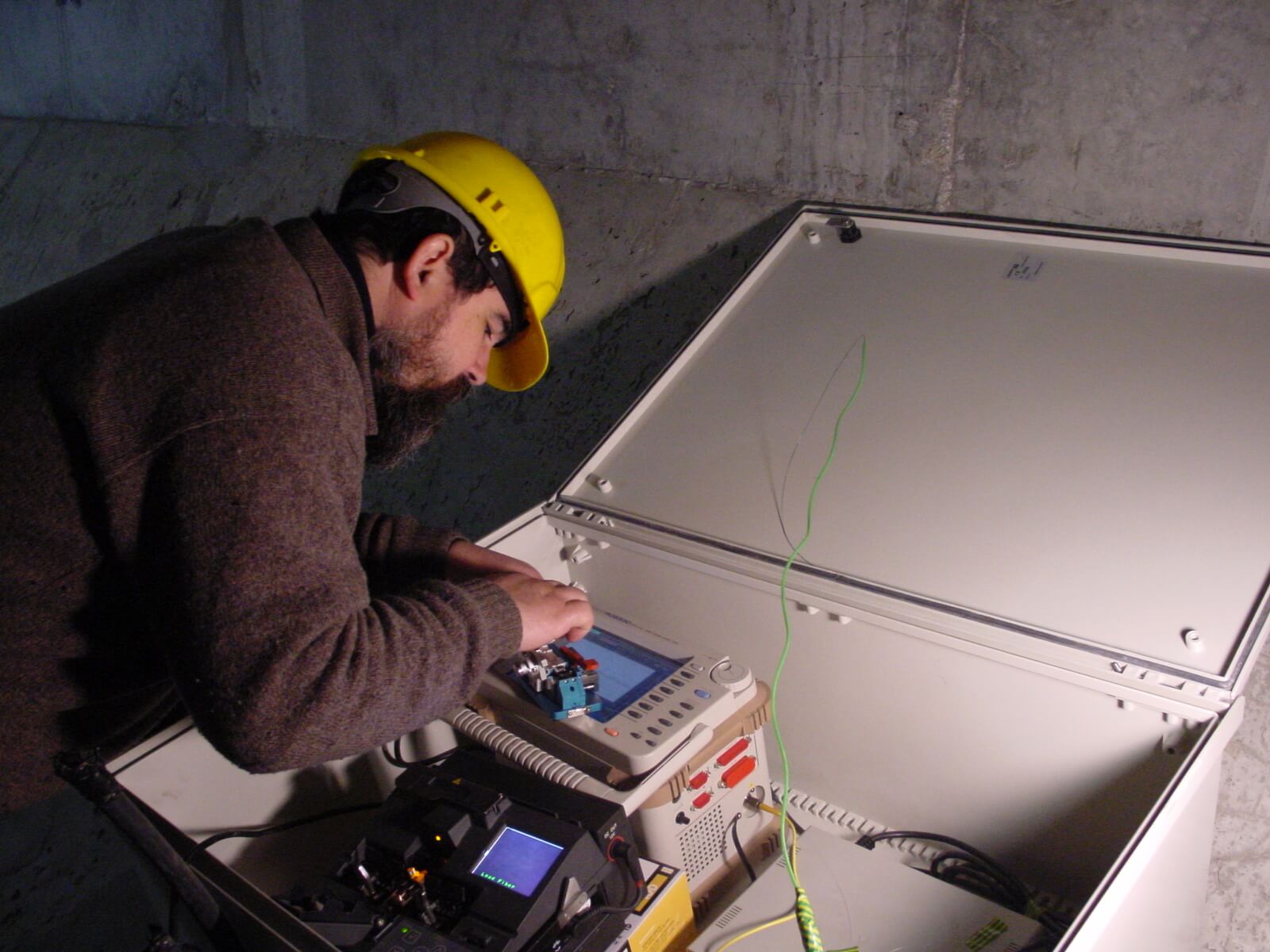

From this point forward, the research in this field gained new momentum with new researchers and new laboratories. Fundamental research focused essentially on two lines: 1) the production of Bragg gratings at INESC TEC and its use for optical fibre sensing and 2) optical fibre lasers.