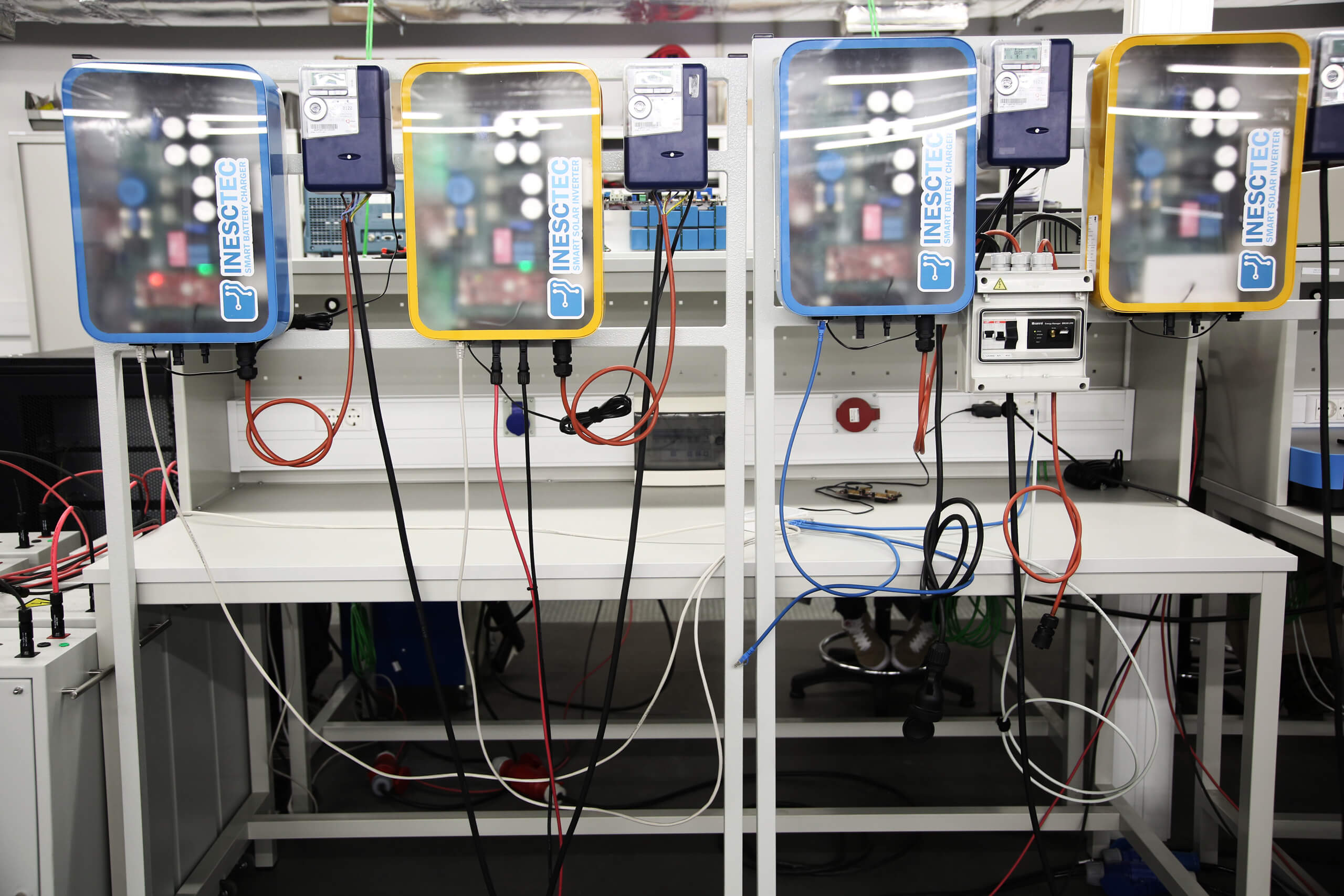

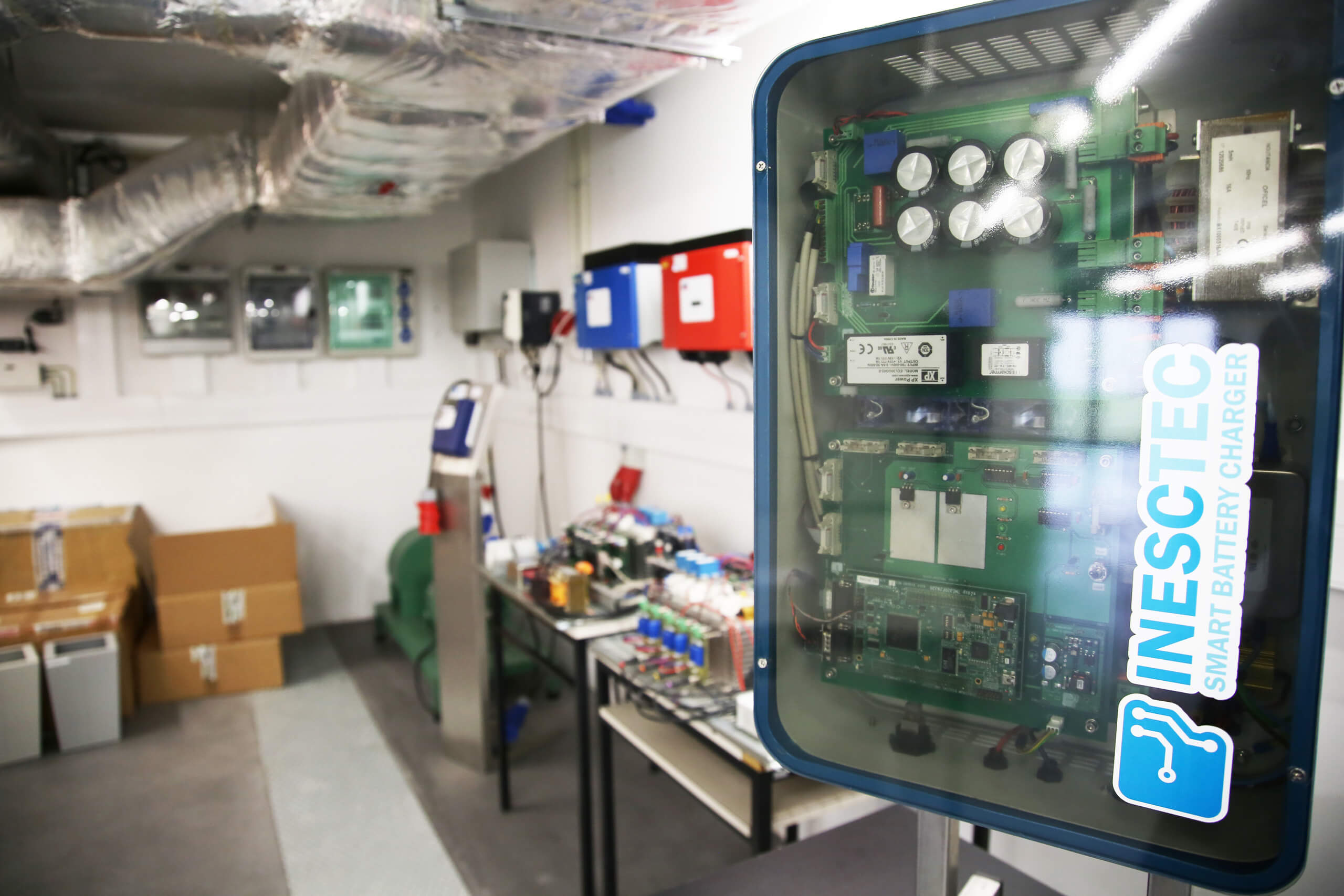

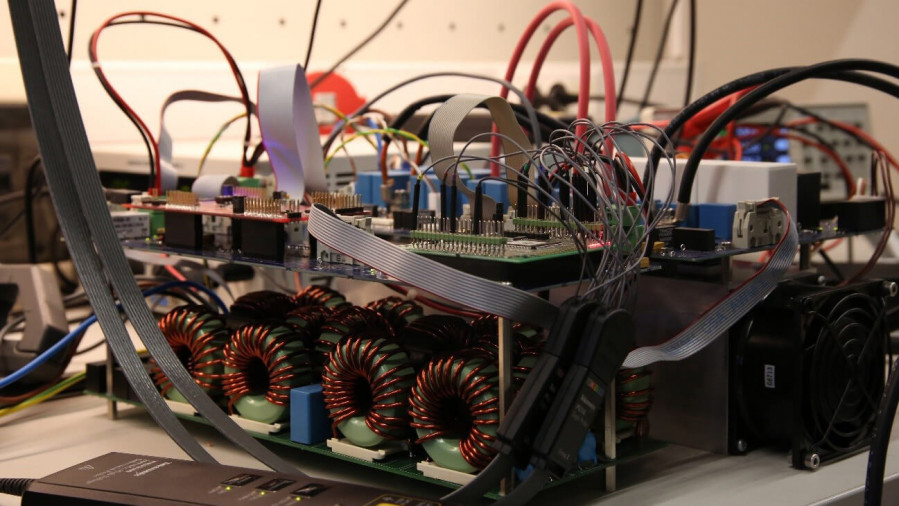

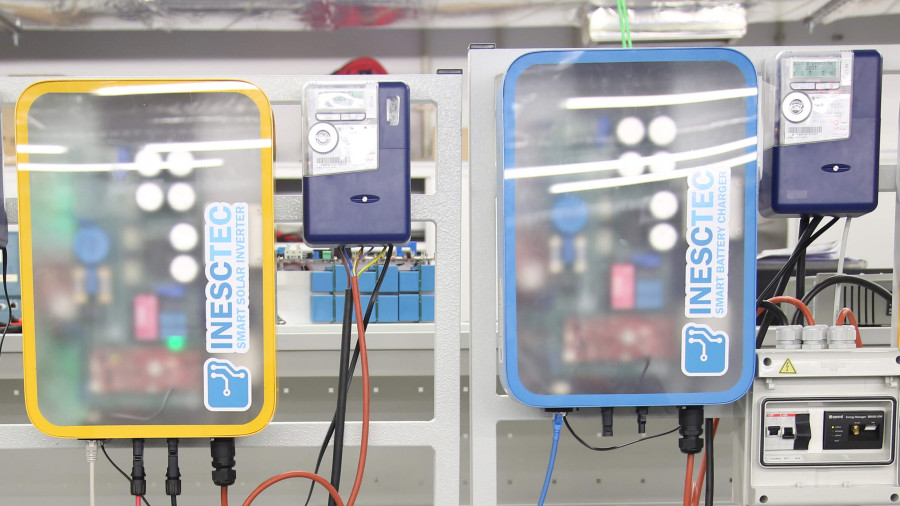

INESC TEC’s Laboratory of Smart Grids and Electric Vehicles (SGEV) makes it possible to put into practice the concepts, algorithms and scientific knowledge generated by the Power & Energy Systems cluster. This implementation ranges from elementary prototypes/proof of concept to complete demonstrators installed in the field.

This facility hosts PhD students and advanced researchers and at the lab they can go through the whole processes idea development, discussion with peers, development of knowledge and prototypes, implementation and testing. This has been a reality in the past years with resident researchers and with invited foreign researchers pursuing PhD degrees.

The laboratory takes the science-based innovation, INESC TEC’s main output, to leading players in the energy market. These companies work in several areas of the energy business ‑ harvesting/production, transmission, distribution, control, protection and conversion.

The laboratory is also a centre for social awareness in energy-related topics, such as energy efficiency, electric mobility, smart grids or renewable energy. Very often the laboratory is visited by young students, researchers and teachers from other areas interested in getting to know the research conducted at INESC TEC.

Created in December 2010 (provisional facilities), today 14 researchers from CPES are using the facility.

Location: INESC TEC Building, FEUP Campus, Porto